While I usually like to get out and about in the mountains and the sea, I have one hobby that I reserve for the wet, windy, and cold winters we have here in Ireland (sometimes the summers are like that too!).

I’ve been fascinated by mechanical watches ever since I was a little kid. To me, they’re a beautiful expression of form following functionality, and despite the competition from digital, beginning in the late 1970s, and the more recent rise of smart devices, there remains a vibrant interest in traditional, mechanical watches.

Watchmaking has always been one of those esoteric arts that I thought would require years of study, as well as tremendous skill and powers of concentration that I’m completely lacking. If you want to make watches professionally, that remains the case, but if you’ve ever wondered how mechanical watches work, and wanted to have a go at taking one apart and putting it back together, the wonderful world of the internet places that within your reach.

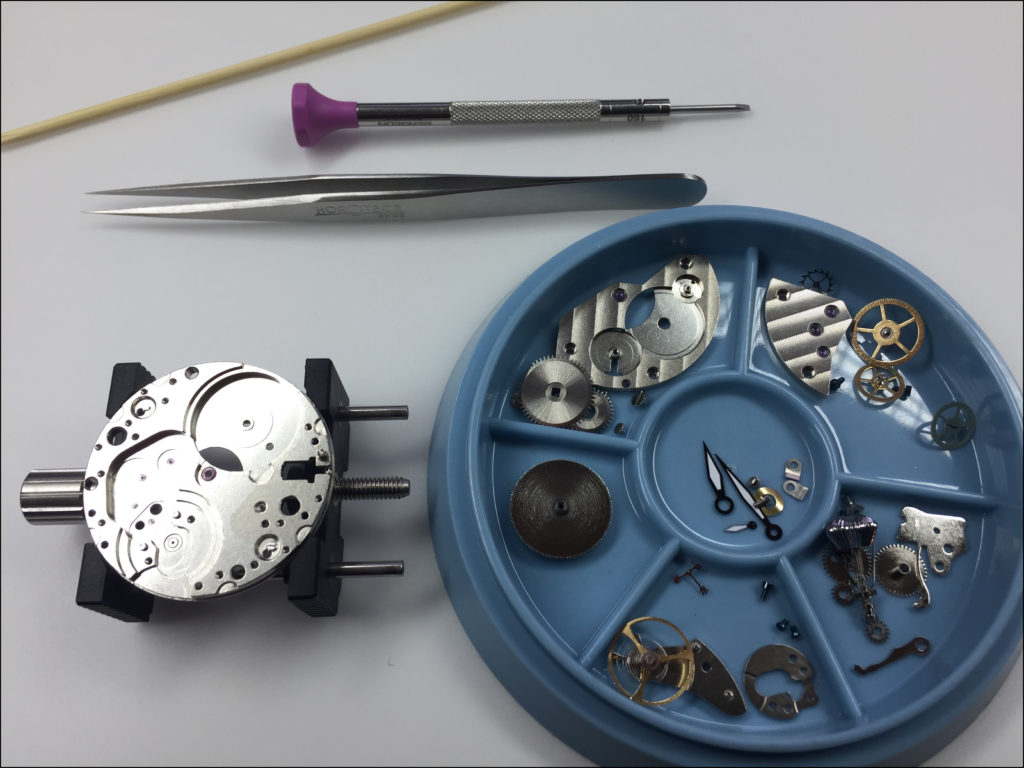

A few years ago, I found a watchmaker’s website that offered exactly what I was looking for. The watchmaker sold a starter kit: a cheap mechanical watch, along with the tools required—loupe, screwdrivers, tweezers, and various other bits and pieces—to do the work. There were step-by-step videos of how to take it apart, how to put it back together, and how to get it working again (hopefully!). I paid my money, and had to practice patience (a very important asset for watchmaking!) for a few days while I waited for my tools and watch to arrive.

I used the time productively, watching the video series a few times so I knew what I was getting into. It all looked pretty straightforward—the fact that the videos were shot through a magnifying lens certainly helped. When the package arrived, I dug straight in.

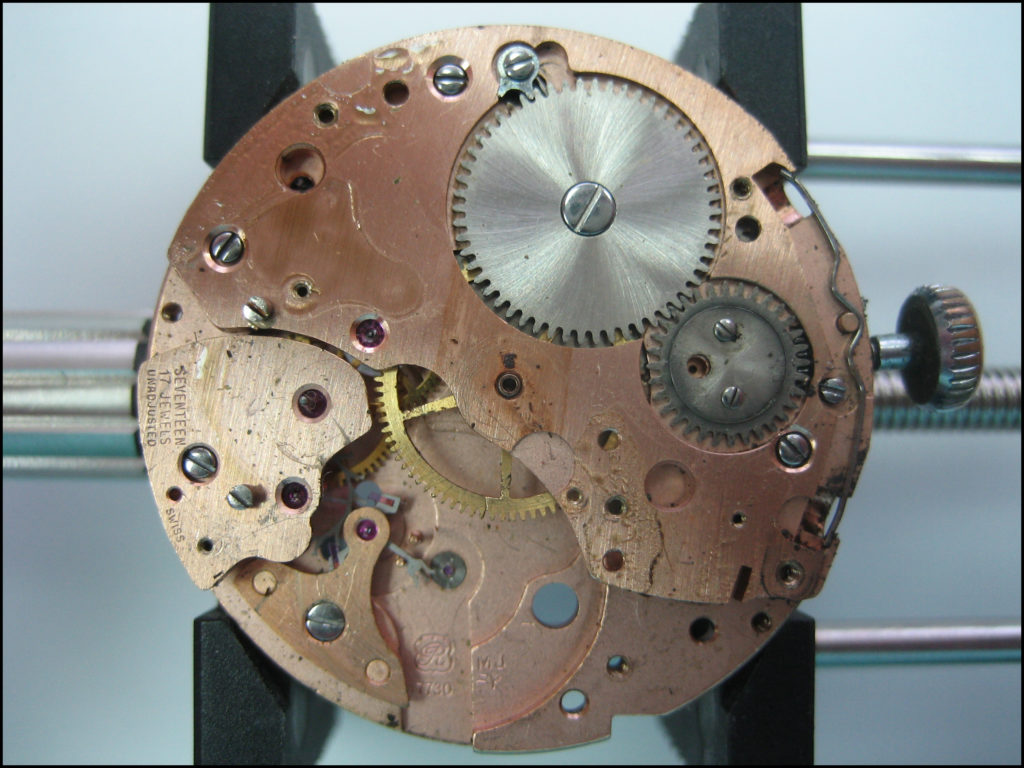

The inside of a mechanical watch—the movement—is a fascinating chain of cogs that will be a dream for anyone who likes Steampunk. It’s a little mechanical wonderland that’s remained largely unchanged for well over a century, from the winding crown that tightens the mainspring, through the centre wheel, third wheel, fourth wheel (which I broke), escape wheel (which I lost), and pallet fork (which I broke), to the balance, which controls how fast or slow the watch runs. Or at least, it should. I broke that too…

Each of the wheels turn at a different rate, and the ones to which the hands are fitted extend up through the dial. Hey presto—time is mastered! The wheels are balanced on pinions that are held in place with small jewels set in bridges that are often highly decorated with different patterns of polishing, adding to the beautiful intricacy of these wonderful little machines.

Placing those bridges on the pinions and screwing them down is where the real skill and patience is required. Snapping the ends off pinions is very easy to do (as I proved—several times!). The screws are very small and will run away the moment you take your eye off them. I have to admit, several remain unaccounted for!

The good news was that the parts cost only cents to replace and could be easily found online. Time for some internet shopping, and another dose of patience. Eventually, the parts arrived, I put the watch back together, and most surprisingly, got it running again.

The watchmaker’s recommendation was to repeat this process a number of times, until you could do it without relying on the videos, and ideally without breaking anything. I don’t think anyone expects to get away without losing the occasional screw! Once that was done, the real fun could begin.

Online auction sites are littered with old watches and movements that no longer work. Some are big, recognisable brands like Omega and Rolex, but many are representatives of older brands, now forgotten, that offered great quality in their day. While some of the movements can be incredibly expensive, others are often surprisingly reasonable. There’s something incredibly satisfying about getting your hands on an old watch movement, cleaning it up, and trying to work out what’s wrong, with a view to repairing it.

A couple of times a year, I trawl the auction sites for a few movements that are beautiful and deserve a little TLC, or have a feature that I find interesting or haven’t worked on before, and they become my projects. Usually it’s just a case of getting the movement cleaned, repaired, and running—a technical challenge—because many of them have long since been removed from their cases and separated from their dials and hands. For me, it’s not about recreating the watch itself; it’s all about getting the movement ticking again!

As with all hobbies, watchmaking has its dangers! In the past, pretty hazardous and radioactive materials were used on watch dials and hands to make them glow in the dark, so you have to be careful which watches you work on, and make sure you aren’t exposing yourself to any of these substances.

While it can be incredibly frustrating when you just can’t work out why a movement won’t run (I have a couple on my workbench that I just can’t get going, even though I can’t see anything wrong), the satisfaction of bringing one of these little machines back to life is huge—when you tighten the final screw, give the crown a couple of winds, and watch the balance wheel jump to life, it’s a really great feeling!

Order Your Copy of Dragonslayer!

Being an old watch/clock maker myself, I really appreciate the article. Hopefully helpful tips for those movements that you can’t get to run: 1. Triple check the mainspring, take it out, clean & re-stretch it, make sure you use the right oil (they get sticky and it sucks power from the train. 2. Double, triple inspect the pivots for wear (you see scoring, re-pivot or re-place the wheel in question. 3. movement together and the pallet fork still removed, give it a little wind “feel” your way back down the train from the escape wheel to “find the friction” (chipped jewel, bent pivot, etc.). With the escapement back in place, check the “beat”: remember “lock, drop, and slide” need to be equal. If it runs out of the case, you are 90% of the way there, and have eliminated all the non-obvious stuff! Thanks again for the entertaining post and good luck with the hobby!